Whether they are used in industrial equipment, food production machines or in office automation and electric motor-driven systems plastic gears offer the advantages of quiet operation and low cost. However, their performance and reliability are significantly influenced by four design and manufacturing constraints: load capacity, tooth geometry accuracy, surface finish, and molding constraints.

1. Strength

Moulded plastic gears have long provided alternatives to metal gearing for lightly-loaded applications. Advances in polymers, scientific plastic moulding design and material processing are allowing them to take over many applications previously reserved for metal gears.

Plastic gears have larger coefficients of thermal expansion and tend to absorb moisture and swell, so good design requires allowance for greater backlash than for metal gearing. Also, they have a greater Total Composite Error so they cannot provide as accurate a mesh.

For proper gear function, you should choose a knurled shaft for maximum load-carrying capacity and a simple press-fit for the lowest residual stresses. Splined or insert-molded hubs require extra mold precision and processing for a secure fit that minimizes distortion with assembly. This also reduces the transfer of heat to the plastic.

2. Durability

Most plastic gears use acetal resins such as DELRIN* or Duracon® with milky white color or MC nylon with blue color (polyamide copolymer). These and other polymers have similar Coefficients of Thermal Expansion, Density and Modulus of Elasticity but they vary with respect to strength, stiffness, dimensional stability and moisture absorption. Detailed design requires accurate, standardized tabular data on these properties.

Plastic gears are not as durable as metals, but they can hold up under heavy loads if designed correctly. A key to durability is a gear geometry that spreads the load over many teeth. This is usually more forgiving of alignment and manufacturing errors than point-contact bevel gears. Also, cross-diametric bevel gears with line contact can handle higher load levels than involute face gears.

3. Lightweight

Plastic gears are more lightweight than their metal counterparts, which can improve performance and reduce costs. They also don’t experience corrosion when exposed to moisture and salt water, making them a good choice for marine applications like boat engines, oil platforms and power generation.

Plastic molded gears can be made of several types of polymers, including Duracon with milky white color (acetal copolymer) and MC nylon with blue color (polyamide resin). Their physical and mechanical properties vary depending on their strength, rigidity, fabrication requirements, dimensional resistance to temperature change and moisture absorption.

They are used in many equipments such as office automation machines, chemical, food and toy industries. They offer advantages such as low wear, quiet and vibration and are easy to be molded and injection molded.

4. Heat Resistance

Many plastics, such as acetal and nylon, have excellent heat resistance. They can withstand extreme temperatures, even when used at high speeds. They are also able to withstand repeated cycles of heat, cold and friction.

The elasticity of plastic gears can absorb static stress that would otherwise bend the teeth. This distributes the load over a larger area and prevents tooth breakage.

In addition, the low levels of density in plastic gears help reduce vibration and noise. This makes them a good option for factories and industrial settings where noise is often a problem. Finally, they are self-lubricating which saves money on the cost of regular lubrication. It is important to choose a lubricant that will work with your plastics. All of these characteristics make plastic gears a great choice for many applications.

5. Self-lubricating

Plastic gears have the advantage of inherent lubricity. They require no additional lubrication when meshing with metal gears as long as the stress level does not exceed their material rating.

Engineering plastics such as POM (Polyacetal) or MC Nylon which is a polyamid resin are used for molding of gears. They can also be thermofused to a metal hub.

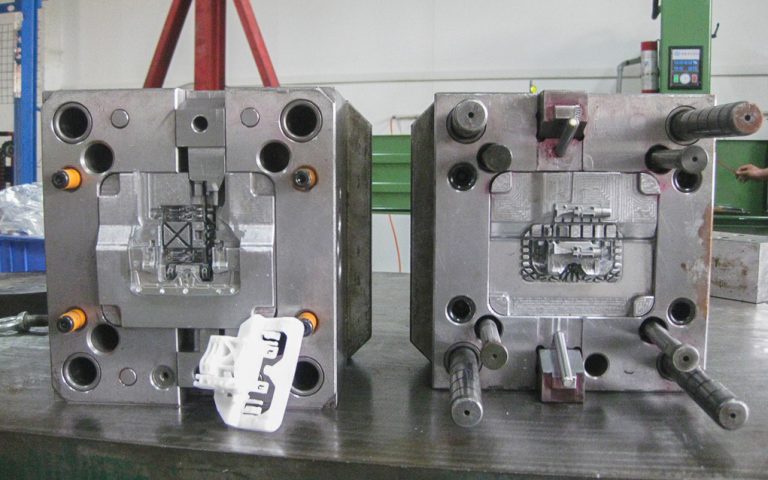

Injection molded plastic gears can be made at relatively low cost and high volume. They are non-rusting and quiet in operation. They can be utilized in food production machines, electronic toys or office automation equipments. They also are ideal for power transmission in drone technologies. Their ability to absorb shock and vibration also contributes to the overall reliability of these products. They also have the advantage of a greater resilience than metal gears.plastic injection molding